MECHANICAL PACKERS

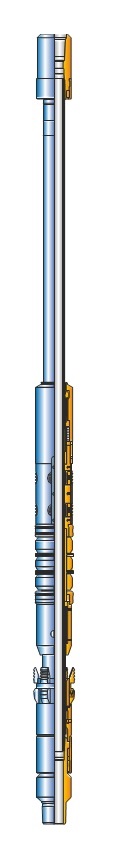

DOUBLE GRIP RETRIEVABLE PACKER MODEL ‘R’

ACT Model-R Double-grip Mechanical Production Packer is a retrievable packer set by compression that isolates the annulus from the production conduit in most production, stimulation, and testing operations. The field-proven design includes rocker slips and a three- element packing system that helps to ensure correct setting and pack off. A hydraulic hold down controls differential pressure from below.

FEATURES, ADVANTAGES AND BENEFITS:

- The packer parts are interchangeable with equipment from other manufacturers, reducing costs and inventory

- The large bypass enables fluids to equalize quickly and reduces the swabbing effect during run-in and retrieval for faster running

- The standard one-quarter right turn for packer setting provides simple operation on the rig

- A differential lock helps to keep the bypass to the mandrel closed and locked during high- pressure operations to maintain integrity and prevent production loss and the need for a workover to pull out of the hole and redress the packer

- The long-stroke mandrel simplifies fluid circulation without packer release

- The packer automatically returns to the run-in position when moved up the hole to enable circulation through and around it

-

Rocker type Slips

Slips with Carbide inserts available - Hydraulic hold down button unit with large internal flow path located below the bypass valve to reduce element swabbing and button wicker dulling

- Surface controlled combination bypass and equalizing valve

OPTIONS:

The packer is available with an

optional left turn for setting

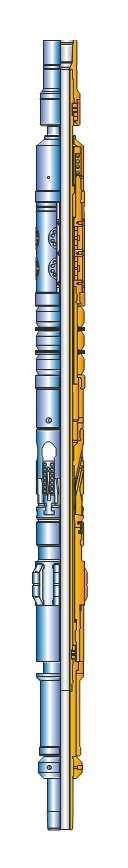

SINGLE GRIP RETRIEVABLE PACKER MODEL ‘R’

ACT Model-R Single-Grip Mechanical Production Packer is a retrievable packer set by compression that isolates the annulus from the production conduit in most production, stimulation, and testing operations. The field-proven design includes rocker slips and a three- element packing system that helps to ensure correct setting and pack off.

FEATURES, ADVANTAGES AND BENEFITS:

- The packer parts are interchangeable with equipment from other manufacturers, reducing costs and inventory

- The large bypass enables fluids to equalize quickly and reduces the swabbing effect during run-in and retrieval for faster running

- The standard one-quarter right turn for packer setting provides simple operation on the rig

- A differential lock helps to keep the bypass to the mandrel closed and locked during high- pressure operations to maintain integrity and prevent production loss and the need for a work over to pull out of the hole and redress the packer

- The long-stroke mandrel simplifies fluid circulation without packer release

- The packer automatically returns to the run-in position when moved up the hole to enable circulation through and around it

OPTIONS:

The

packer is available with an optional

left turn for setting.

MODEL “TST-1” MECHANICAL SET PACKER

The ACT TST-1 Retrievable Packer is a heavy duty service packer ideally suited for all types of squeeze cementing, formation fracturing, high pressure acidizing, etc. It is a large opening compression set packer with hydraulic button-type hold down. It withstands high pressure from above or below and uses a three-element packing system, L-slot, and a drag block mechanism for easy setting. The tool features a proven three element packing system and hydraulically controlled balance sleeve designed to keep the by-pass valve closed when set.

FEATURES:

- Sets securely in any hardness casing, including premium grades

- Three piece packing element systems with metal backups accommodate low and high pressure applications for the broadest range of services

- Hydraulic hold down button unit with large internal flow path located below the bypass valve to reduce element swabbing and button wicker dulling

- These hold down piston type slips are set by pressure from below

-

TSurface controlled combination

bypass and equalizing valve

Automatic L-slot Unit, setting the packer is accomplished by running to depth rotating 3/4 turns to the right and setting down - Straight pickup of the tubing will first open the bypass valve and equalize pressure continued pickup will release the packer and automatically engage the packer in the running position for further operations up or down the hole

- All Thread connection comes standard in API IF/EUE thread form

- All Pressure bearing o-rings for higher pressure resistance

-

Load and pressure resistance

designed to meet high load

applications

P110 body, coupling and sub for heavier duty jobs

STORM VALVE

ACT Storm Valve is run above the TST-1 compression set service packer to isolate the tubing below the packer for disconnection during a weather emergency or surface equipment repair. The valve has a J overshot running tool, which a quarter turn disconnects. This quick, safe, cost-effective well closing requires no tubing pulling. The valve can be repeatedly opened and closed, independent of the disconnection feature, enabling packer-pressure testing before disconnection. The heavy-duty bearing assembly enables free valve operation with the running string in compression, easing operation on floating rigs. Before packer retrieval, the string can be reconnected and the valve opened to equalize pressure.

Application:

- Weather emergencies

- Wellhead repair

FEATURES, ADVANTAGES AND

BENEFITS:

- The rugged alloy-steel construction ensures dependability

- The internal-flush (IF) drillpipe tool-joint thread connections provide exceptional, field- proven torsional strength for rigs

- The simple, field-proven design eases valve operation and redressing

- The J-tool disconnects with a quarter turn of the running string, providing fast, efficient valve placement

- The valve can be opened and closed repeatedly with two quick turns, independent of the disconnection feature, enabling the packer to be pressure tested before disconnection to ensure its integrity

- The expandable plug provides through-bore access for circulation and wirelines

AS1-XHP MECHANICAL PACKER

he ACT AS1-XHP Packer is the most versatile of the mechanically set retrievable packers and may be used in any production application. Treating, testing, injecting, pumping wells, flowing wells, deep or shallow, the AS1-XHP is suited. The packer can be left in tension or compression, depending on well conditions and the required application. A large internal by-pass reduces swabbing when running and retrieving. The by-pass closes when the packer is set and opens prior to releasing the upper slips when retrieving to allow pressure equalization. The J-slot design allows easy setting and releasing; 1/4 turn right-hand set, right-hand release. A patented upper-slip releasing system reduces the force required to release the packer. A non directional slip is released first, making it easier to release the other slips. The AS1-XHP packer can withstand 10,000 psi (69 MPa) of differential pressure above or below.

FEATURES, ADVANTAGES AND BENEFITS:

- The design holds high differential pressure from above or below, enabling the packer to meet most production, stimulation, and injection needs

- The packer can be set with compression, tension, or wire line, enabling deployment in shallow and deep applications

- The packer can be set and released with only a one-quarter turn of the tubing

- The bypass valve is below the upper slips so that debris are washed from the slips when the valve is opened, reducing the times for circulation and total retrieval

- The full opening enables unrestricted flow and the passage of wire line tools and other packer systems

- The packer can be run with the T-2 on-off tool, which enables the tubing to be disconnected and retrieved without retrieving the packer

OPTIONS:

- Elastomer options are available for hostile environments.

- Optional safety releases are available.

AS1-X MECHANICAL PACKER

suited for all. The packer can be left in tension or compression, depending on well conditions and the required application. A large internal by-pass reduces swabbing when running and retrieving. The by-pass closes when the packer is set and opens prior to releasing the upper slips when retrieving to allow pressure equalization. The J-slot design allows easy setting and releasing; 1/4 turn right-hand set, right-hand release. A patented upper-slip releasing system reduces the force required to release the packer. A non directional slip is released first, making it easier to release the other slips. The AS1-X packer can withstand 7,000 psi (48 MPa) of differential pressure above or below.

FEATURES, ADVANTAGES AND BENEFITS:

- The design holds high differential pressure from above or below, enabling the packer to meet most production, stimulation, and injection needs

- The packer can be set with compression, tension, or wire line, enabling deployment in shallow and deep applications

- The packer can be set and released with only a one-quarter turn of the tubing

- The bypass valve is below the upper slips so that debris are washed from the slips when the valve is opened, reducing the times for circulation and total retrieval

- The full opening enables unrestricted flow and the passage of wire line tools and other packer systems

- The packer can be run with the T-2 on-off tool, which enables the tubing to be disconnected and retrieved without retrieving the packer

OPTIONS:

- Elastomer options are available for hostile environments

- Optional safety releases are available

PACKER MILLING TOOL

TENSION PACKER

The ACT Tension Packer is a

retrievable, single grip tension set

packer, used in water flood, oil

production or treating applications.

This compact, economical packer is

used for shallow wells where

sufficient set down weight is not

available to utilize a set down

packer. It is set by left hand

rotation and has three release

methods.

- Sets securely in any hardness casing, including premium grades

- Compact, short, easy to transport and run

- Full opening enables maximum fluid circulation

- Rocker type slips eliminates the need for extra drag block

- Easy to operate – a simple and reliable J-Slot mechanism, actuated from the surface by tubing rotation, makes the packer easy to set and release

- One piece packing Three release methods, normal release, shear release and safety joint release

OPERATION:

- Run the packer to desired setting depth, and make the last movement down before attempting actual set

- Rotate the tubing to the left one-quarter turn at the tool, and pick-up on the tubing string to obtain pack-off.

- To release the packer, Lower the tubing string at least one foot more than is necessary to remove the applied tension (this will move the J-Pin to the top of the J-Slot) and rotate to the right sufficiently to obtain one-quarter turn at the packer. Should the Packer fail to release with normal procedures, an upward pull of the tubing string weight, plus 25,000 to 50,000 lbs. tension (dependent on strength of the shear ring) will release the packer. If it is not desirable or practical to pull 50,000 lbs. through the tubing, apply approximately 10,000 lbs. strain and rotate the tubing 15 to 20 turns to the right. This unscrews the left- hand safety thread between the Top Sub and the Body and allows removal of the tubing string and the Top Sub. To remove the remaining portion of the Packer, install a set of Jars made up above an overshot, or spear, engage the Packer Body, and actuate the Jars to free the Packer Body from the casing. Tension Packers are available for 4.1/2” to 9.5/8” casing sizes.

TUBING ANCHOR CATCHERINDEXING MULE SHOE

The Tubing Anchor Catcher (TAC) is

one of the most important tools in

achieving efficient rod pumping

operation. Run below a sucker rod

pump, it acts as an anchor to the

lower end of the tubing string to

maintain tension in the tubing

string and eliminates tubing

movement during the pump cycle. It

also acts as a tubing catcher to

prevent parted pipe from falling

into the well.

Rod pumping operation, with the

tubing hanging free, causes problems

like excessive wear of the rods,

tubing, casing, and pump, reduced

pumping efficiency, increased

operating costs such as increased

requirements of power consumption

etc. The elongation and contraction

of the tubing string along with the

rod string reduces the effective

pump stroke and thus reduces the

production rate. This also causes

tubing buckling which results in

tubing and casing wear, tubing

collar leaks, and metal fatigue

causing the tubing to part.

FEATURES:

- Increases pump efficiency Reduces operating cost by reducing maintenance and down time caused by casing, tubing or sucker rod wear

-

Simple operation: Rotates left to

set, right to release

Double grip slip prevents upward and downward movement -

Catches parted tubing

Straight pull emergency release with adjustable shear pin force

Easy and inexpensive to redress.

OPERATION:

Install the Anchor Catcher in

the Tubing String just below or

above the pump for best results. Run

to desired depth and rotate the

tubing to the left to set the Anchor

Catcher. To ensure the Anchor Slips

are solidly engaged with the casing,

hold left hand torque on the tubing

and pick up and set down several

times to be sure the Anchor Slips

are properly set in the casing. The

tubing will torque up when the slips

have set. Release the torque and

apply the required amount of tubing

tension.During this slip setting

operation, the strain should be at

least equal to the final strain that

will be needed plus full tubing

set-down weight.To pull the Anchor

Catcher, lower the tubing to release

the tension and rotate to the right

while working the tubing up and down

slightly. Should the Anchor Catcher

fail to release with normal

procedures, an upward pull of the

tubing string weight, plus the total

value of the Shear Pins will release

the Anchor.Tubing Anchor Catchers

are available for 4.1/2” to 9.5/8”

casing sizes.

T-2 ON/OFF TOOL

ACT T-2 On-Off Tool enables the

tubing string to be disconnected

above a packer for zonal isolation,

tubing retrieval, and temporary zone

abandonment. The tool contains an

internal lock profile for landing a

wireline plug to provide zonal

isolation below the packer. The tool

has two basic components, the

overshot mounted on the tubing

string and the stinger mounted on

the packer. The overshot disengages

with either a standard left release

or an optional right quarter-turn

release. Shear- up or shear-down

positions are compatible with the

packer setting and retrieving

styles.

The washover shoe on the overshot

cuts through debris. The seals in

the tool are retrieved with the

overshot to enable redressing at the

surface. Available with all common

wireline profiles, the stinger works

with industry standard blanking

plugs, standing valves, and

regulators.

APPLICATIONS:

- Mechanical, hydraulic, or wireline-set packer completions

- Zonal isolation above the packer

- Temporary abandonment of lower zones

- Tubing retrieval without disturbing the packer

FEATURES, ADVANTAGES AND

BENEFITS:

- The tool enables the packer to be used as a bridge plug for zonal isolation or the temporary abandonment of lower zones, saving rig costs

-

The tool can be full-pressure

tested at the surface to save rig

time

The tool can be pinned in a shear-up or shear-down position, providing compatibility with the packer setting and retrieving style - The standard left or optional right quarter-turn release provides simple operation on the rig

- Bonded seals enable multiple disconnections without costly retrieval

- The rugged, dependable design enables tubing retrieval without disturbing the packer

- The washover shoe cuts through debris to release stuck equipment in the wellbore

OPTIONS:

- The tool is available in a variety of materials

- An optional right quarter-turn release is available for the overshot disengagement

- The stinger is available with all common wireline profiles

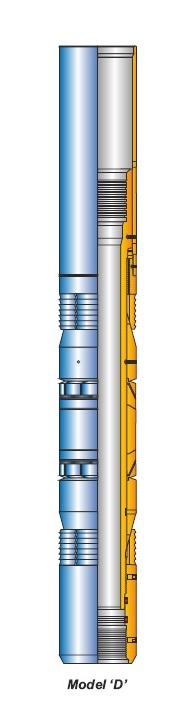

MODEL ‘D’ & ‘F’ PERMANENT PACKERS

The ACT Model ‘D’ & ‘F’ Production Packers are available to fit your needs and provide the versatility of our excellent pack-off system for a positive secure set in the well bore. These packers assist in the economical operation of a variety of completion and production jobs. These are designed to accommodate seal bore extensions used in deep wells requiring a longer seal bore interval. Seal Nipples are available with either automatic square-thread latch or locating shoulder. These packers can be used as test tools. Full opening bores allow the passage of perforating guns used to perforate a zone below for testing. If the zone proves to be non-productive, the packer can be used as a squeeze tool. The packers are designed to provide high-impact resistance and a dependable seal. The high quality packing system will conform to the casing and close off any extrusion of rubber, as the packer is set, even at high temperatures and pressures. ACT Model ‘D’ Production Packers provide excellent clearance for run-in while the ACT Model ‘F’ Production Packers offer a larger seal bore. The two models carry different pressure ratings noted later in this document. R22 is the designation for standard service that ACT puts on the equipment listed below. Equipment for service other than standard can be specified upon request from the customer. For additional information, please contact ACT or an authorised representative.

Features:

- One piece slips hardened to depth of wicker only

- Sets in any grade casing including P-10

- Choice of bottom to fit your application – specified when ordering

- Re-attaching lock ring holds setting force

MODEL DB HYDRAULIC SET PERMANENT PACKER

ACT Hydraulic-Set Dual Bore Permanent Production Packers are the hydraulically set one-trip completion packers, ideal for high volume production in high angle, extremely deviated well. These packers feature the largest possible bore through combined packer and seal accessory. The packer is run on the hydro-set anchor latch seal unit which is made up in the top of the packer via the left-hand threads on the latch and is set by applied tubing pressure. The DB packer requires some type of temporary plugging device such as a shear out plug or wireline blanking plug located close to the end of the tubing.

ADVANTAGES:

- Slim-line design

- Solid construction enables 50% faster run-in without fear of impact damage or premature setting, making significant rig-time savings possible

- Two opposed sets of full-circle, full-strength slips ensure packer will remain properly set

- Packing element resists swab-off and packs off securely when packer is set

- Unique interlocking, expandable, metal backup rings contact casing, creating a positive barrier to packing element extrusion

ADDITIONAL INFORMATION:

The Dual Bore Permanent Hydraulic Set

Packers have been designed to give maximum

strength, uniformity of setting pressure and

standardization of all alloy materials for H2S

service.

LOCATOR TUBING SEAL ASSEMBLY

ACT Locator Tubing Seal Assembly is the most basic packer sealing system for packers incorporating a sealing bore. It is run in the well on the production tubing string until its No-Go shoulder locates on the to of the packer. This positions one or more seal stacks in the packer’s seal bore and establishes a seal between the packer and tubing. When a locator tubing-seal assembly is landed in a packer, the tubing is normally set in compression to compensate for any contraction of the tubing during treating operations. However, it is not always possible or desirable to slack off sufficient weight, particularly in deep deviated wells. In such cases, additional length must be added to the packer’s seal bore using seal bore extensions and to the locator tubing-seal assembly using a combination of spacer tubes and additional seal units.

SEAL BORE EXTENSION

ACT Seal Bore Extension is used in completions where seal bore packer is used as a production packer and tubing movement is expected. Seal Bore Extension provides sufficient seal bore length so that long seal assemblies accommodate tubing movement while always remaining in the seal bore. Multiple seal bore extension can be coupled together using a concentric coupling to obtain more seal bore length. Seal Bore Extensions are available for all sizes of seal bore packer. Seal Bore Extension are manufactured from materials that comply with NACE MR0175 STD. For SSC resistant metallic material.

Application:

Completions

with seal bore production packers where tubing

movement is expected.

Benefits:

Easy to

install

Low cost solution

Facilitates

tubing replacement

ANCHOR LATCH SEAL ASSEMBLY

The ACT Anchor Latch Seal Assembly positions the

seal units in the polished bore of the packer at

the bottom of the available stroke. With a

slight amount of set-down weight, the anchor

latch will snap into the top thread of the

packer. This feature allows the upward pull to

be applied to the tubing string to positively

confirm proper location and operation.The

process to release the anchor is an upward pull

combined with right hand turns of the tubing at

the latch. The releasing mechanism of the anchor

makes it ideal for completions where tubing

movement is not desirable.

Standard anchor

latch assemblies are manufactured from materials

that comply with NACE MR0175 standards for

sulfide stress cracking-resistant metallic

materials and fitted with seal stacks with metal

backups. Viton, Aflas, and Chevron seals are

available for hostile conditions, such as

high-temperature, high-pressure, and sour

environments.

FEATURES:

- Easy snap-in-snap-out procedure

- Prevention of seal movement

- High-performance seals available for hostile environments

PACKER RETRIEVING TOOL

The ACT Packer Retrieving Tool is required to retrieve seal bore hydraulic set retrievable packer. Each packer has a unique retrieving tool but all have same basic design. Latch feature latch into the top thread of the packer. A pull shear the shear screw of collet support and release the packer. If packer cannot be released with the help of right hand rotation collet will be free from safety nut and latch can be backed out.

PACKER MILLING TOOL

General Description

The

ACT PRS Packer Milling Tools (Packer Retriever)

is an internally engaging fishing tool designed

for the retrieving of production packers. With

its accessory components (Stinger, Bushing and

Mill Shoe) it passes through the bore of the

packer, mills the packer slips loose and pulls

the packer after it has been milled over, all in

one trip. A Packer Retriever is assembled with

the proper size slip to engage the bottom of a

specific bore packer, and made up on the lower

end of sufficiently long stinger (extension) to

permit the Retriever to be lowered completely

through the packer during the milling operation.

The Bushing is provided with a box connection at

its lower end to attach the Stinger, also a pin

connection at the lower end for attaching Mill

Shoe, and a pin or box connection at its upper

end for connection to the run-in or fishing

string.

OPERATION:

Make up a complete ACT PRS Packer Milling

Tools consisting of Retriever, Stinger, Bushing

and Mill Shoe. Make sure that the tool is

compatible with Casing and Packer sizes and will

permit proper and safe operations of the milling

and retrieving operations.

Lower the

fishing string until the Mill Shoe contacts the

slips of the packer. Milling operations may

begin until drill off conditions are

established. Generally, light drill loads should

be used to start to enable the shoe to cut the

thin bevel upper parts of most packers away

until full mill shoe face contact is

established. Additional weight may be added to

establish optimum conditions. Rotary Speeds must

be established that are sufficient with a given

weight, to burn or abrade the carbide particle

matrix away to expose the successive new cutting

edges of carbide particles. When this condition

is established the Mill Shoe will cut almost any

metal with maximum efficiency. Start circulation

and right-hand rotation to mill away the slips

and seating element of packer. When the packer

begins to slide down the hole, stop rotation,

raise the fishing string to engage Packer

Retriever with packer and then pull the assembly

and fish from the hole. The best condition of

removal for most makes of full bore production

packers is to mill up the upper slips and

approx. half of the packing element before

retrieval is attempted.

TO RELEASE THE RETRIEVER

For any of several reasons, it may be

required to release the Retriever from the

packer. Release of the Retriever is accomplished

by elevating the fishing string until weight is

indicated. Lower the fishing string about three

to four inches. Rotate the string right hand and

slowly elevate the string to withdraw the

Retriever from the packer.

CONFIRM THE FOLLOWING:

-

That the Retriever is assembled with the

correct size slip for the packer to be

That the Stringer is sufficiently long to permit the Retriever to pass completely through the

That the Bushing and Mill Shoe are the correct size for the casing - Make up complete assembly to the fishing string. (Scrapers or drift tools should be run prior to running the Milling Tool to depth. The casing in which the packer is to be removed should be washed clean to the packer top and a fluid and pump equipment must be selected that will clean the mill shoe and remove all cuttings from the hole as the packer is mill-up)

- Lower the Retriever in to the hole on the fishing string and pass it through the packer. The Retriever must clear the packer bore and be in a free position below the packer before milling or rotating of the string. If there are restrictions below the packer such as perforated nipples, landing subs or tail pipe, extensions must be used to position the packer retriever well below these points so that the rotation of the string will not foul the Packer Retriever. Now, raise the fishing string slowly and carefully until it takes weight. This ensures that the Retriever will engage the packer seat.

MAINTENANCE

To guard

against mis-runs and to prolong the life of the

ACT PRS Packer Retriever it should be completely

disassembled, thoroughly cleaned, lubricated and

reassembled before storing. Exterior surfaces

may be either painted or lubricated to prevent

rust and deterioration.

INDEXING MULE SHOE

The ACT Indexing Mule Shoe facilitates stab in of seals into seal bores, even in deviated wells. The work string does not need to be rotated to orient the mule shoe. Axial movement of the work string against an obstruction rotates the mule shoe. If it still fails to enter the bore, the work string is lifted to re-engage the internal J-mechanism and the mule shoe will again rotate when set down load is applied.

KEY BENEFITS:

- Protected spring. Spring is not exposed either in the inner or outer portion of the tool

-

Spring cannot be overstressed, as set down

weight is taken through a load shoulder in the

tool

Internal bearings prevent spring wind-up during the indexing process

APPLICATION:

Stabbing in

seals into seal bore in deviated wells.

HYDRAULIC SETTING TOOL

ACT MODEL D, F AND ERD PACKER, can be set on tubing or drillpipe using a wireline adapter kit and a hydraulic setting assembly. These setting assemblies are particularly useful for setting permanent packers in high-angle, deviated wells such as those drilled offshore. The hydraulic setting tool assembly and packer are run to setting depth on the tubing string and a ball is dropped to the ball seat in the setting tool. Sufficient tubing pressure is then applied to set and pack off the packer. The pressure or combined pressure and tubing tension, parts the release stud in the adapter kit and frees the setting assembly from the packer for retrieval. The HST has a bottom connection that accepts common wireline-setting tool adapter kits.

APPLICATIONS:

-

Deviated or horizontal wells

Large-casing packers - Wireline-set seal bore packer completions

FEATURES, ADVANTAGES AND BENEFITS:

- The HST accepts common wireline adapter kits, enabling it to set all ACT permanent and retrievable seal bore packers

- The HST enables the well to be circulated before the packer is set, preventing debris accumulation

- The heavy-duty HST construction enables the packer assembly to be pushed into place in high-angle and horizontal wells, enabling the packer to be set where wireline deployment is difficult or impractical