HYDRAULIC PACKERS

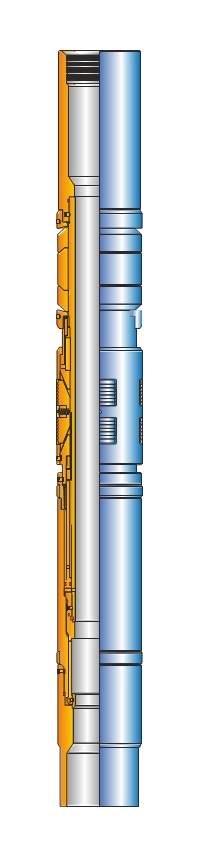

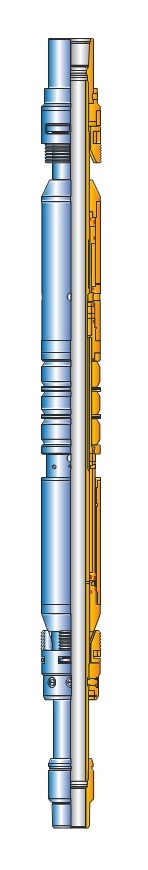

RHP – DB DUAL BORE HYDRAULIC SET RETRIEVABLE PACKER

The ACT MODEL RHP-DB Retrievable Packer delivers high performance with simplicity of design and desirable economics. The dual bore packer allows for a large ID through the packer by sealing in an upper seal bore. No tubing rotation required to fully set the packer. It has one-piece, self energizing packing element and features bidirectional slips below the packing element for maximum protection from debris fouling. This location protects the slips from being lost during retrieval or milling. A retrieving tool is required to retrieve these packers.

FEATURES:

- Simple design

- Easy to retrieve

- Large seal bore

- Hydraulic setting

- Hydraulically setting the packer avoids the need to rotate the work string in running or retrieving the packer, which simplifies procedures, improves efficiency, and saves rig time.

- The ECNER array system reduces the swab-off effect and facilitates center pack off by enabling supporting force to be applied to the outer elements.

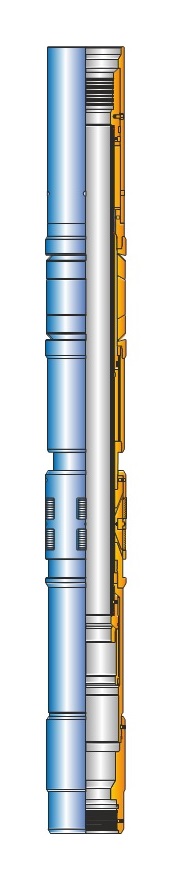

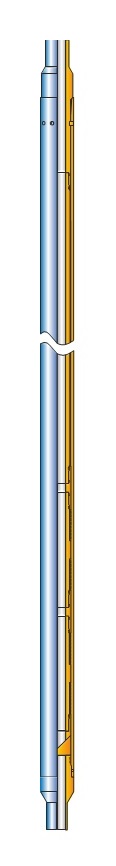

ERD RETRIEVABLE SEAL BORE PACKER ‘R’

ACT Model ERD Retrievable Hydraulic Seal Bore Packer is a Retrievable Packer. Hydraulically set by pressure in the tubing. It is run with Hydraulic Setting Tool & retrieving is done independently from the Tubing, using a Retrieving Tool manipulated on a work string. This packer is ideally suited for highly deviated well both onshore & offshore.

APPLICATIONS:

Model ERD Retrievable Hydraulic Seal

Bore Packer can be use in oil

production wells or in water or gas

injection wells.

FEATURES, ADVANTAGES AND BENEFITS:

- Run & set with the Production Tubing Hydraulically setting eliminates the requirements for spacing out & opening & closing with the help of Sliding Sleeves for the displacement of fluids

- Effects on tubing (compression & tension) are transmitted to slips- there is no shear ring with limits these stresses

- Retrieval independent of the tubing using a Retrieving Tool. It can be lift to the bottom of the well with a By-Pass Blanking Plug in a Nipple to isolate the formation

MODEL FURY 25 HYDRAULIC SETTING TOOL

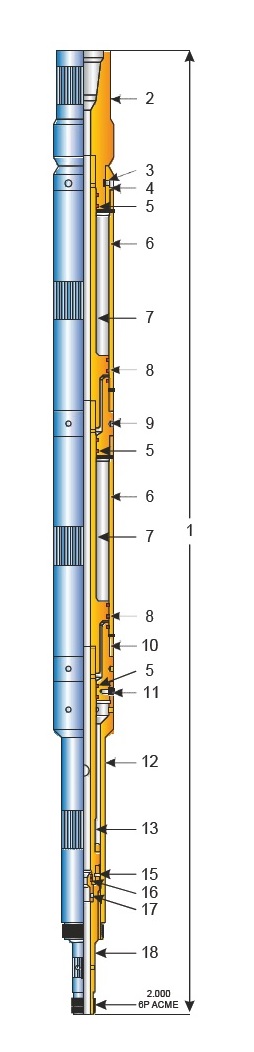

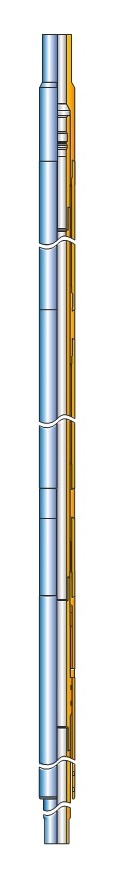

MODEL RHP-SR RETRIEVABLE HYDRAULIC PACKER SINGLE STRING

American Completion Tool Model

RHP-SR is a hydraulic set packer

that can be run in single or

multiple zone installations. It is

highly recommended for deviated

wells where conditions are not

suitable for mechanical or wireline

set packers. No tubing movement is

required or generated in order to

set the packer. This allows the well

to be kept positively controlled at

all times because the tubing is

landed and the wellhead installed

before circulating or displacing

well fluids prior to setting the

packer. Two or more packers can be

set either at once or in any desired

sequence.

The RHP-SR packer design features

bi-directional, one piece slips

located below a three element

packing system consisting of dual

durometer rubber elements. The slips

are fully enclosed in a shear pinned

slip housing which in turn is

protected by a full diameter guide

located below the slip housing. The

RHP-SR packer requires a means of

establishing a maximum of 3,500 psi

pressure inside the tubing at the

packer (for 7″ and smaller).

The hydraulic setting chamber is

adjustable between 900 to 2,500 psi

which allows the tubing to be

pressure tested before the packer

begins to stroke and set. Two

balanced pistons are utilized during

the setting process. The lower

piston moves down to set and anchor

the slips before the upper piston

moves upward to compress the

packing. This action imparts the

total setting force to both slips

and packing thus assuring a positive

anchor and pack-off. The pack-off is

retained by a one-piece ratchet ring

that locks in and stores the setting

force applied to both the slips and

packing elements.

The RHP-SR packer incorporates two

methods of release, straight pull or

rotation. Both methods are contained

in the same releasing nut which is

located at the upper end of the

packer. Straight pull release is

accomplished by shearing a

predetermined quantity of brass

retaining screws which frees the

tubing. Rotation release is

accomplished by approximately eight

right hand turns of the tubing which

also frees the packer. Straight pull

then is applied to completely relax

the packer for retrieval. The RHP-SR

packer can be ordered with only one

method of release if desired. A

positive acting equalizing valve is

also located in the releasing

section which automatically opens

during the releasing procedure to

equalize pressures and allow

circulation between the annulus and

tubing. In addition, a large

diameter fluid by-pass is located

inside the packing mandrel which

allows fluid passage for rapid

retrieving while reducing element

swabbing.

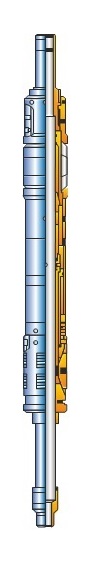

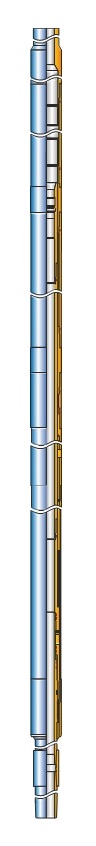

RHP-SPR HYDRAULIC SET RETRIEVABLE PACKER

The ACT RHP-SPR Packer is a hydraulic set single-string retrievable packer and may be used in virtually any production application. Tubing pump pressure is used to set the packer and the setting force is locked into the packer by a body lock ring. A large internal by-pass reduces swabbing when running and retrieving. The by-pass closes when the packer is set, and opens during the releasing process to allow pressure equalization. Shear screws are used to control the packer release. The shear release value is adjustable by adding or removing screws from the shear housing or by use of steel screws. The standard ACT Packers are designed for differential pressures up to 7,500 psi.

FEATURES:

- The straight-pull, shear-release pins are unaffected by differential pressure, enabling easy changes to the release force before running

- The double-grip system enables the packer to hold differential pressures securely from above and below, preventing packing-element movement and ensuring proper pack off

- All components are locked to prevent pressure build up or debris from pre-setting the packer, improving reliability when running the packer in the wellbore

- Adjustable shear release Straight pull release

POLISHED SEAL BORE RECEPTACLE

The ACT Polished Seal Bore Receptacle is designed for applications where a large ID must be maintained through the completion while accommodating extreme tubing movements. The ACT Polished Seal Bore Receptacle modular design allows tool to be easily converted from tension release to hydraulic release. The tension release and the hydraulic release incorporate a Polished Seal Bore Receptacle as well as a PBR seal assembly including 2 sets of working seal units and a debris barrier above and below the working seals. Both versions when combined with a hydraulic or hydraulic/ hydrostatic set can be run in and set in one trip. The polished seal bore receptacle can be retrieved in two trips. The seal assembly is retrieved when the tubing string is recovered. The PBR seal bore is retrieved with a PBR retrieving tool. The Polished Seal Bore Receptacle is available in varying lengths of up to 25 ft. in stroke. An adjustable shear mechanism locks the outer housing and seal mandrel together during run- in. Once the seal assembly is released, it is free to move in the bore, compensating for tubing movement. The PBR assembly can be pinned in the fully stroked, closed or midway position to accommodate pre-spacing in one-trip completions

APPLICATIONS:- One-trip installations in deviated or horizontal wells

- Large-bore, high-flow-rate applications

- Production, injection, or stimulation Monobore completions

- One-piece polished bore housing

- Full bore-seal mandrel allows passage of intervention tools

- Adjustable shear-release mechanism

- Rocker type slips eliminates the need for extra drag block

- Available with premium materials and connections

- Available in stroke lengths up to 25 ft.

- Metal-to-metal connections for hostile environments

- Debris barrier above and below seals for long life

- Seals are retrieved on the tubing string

- Threaded receptacle on top for PBR retrieval on workstring

BENEFITS:

-

Maximum-flow capability

Retrieves separately from the packer, simplifying removal - Rugged design for rotating into liner tops and horizontal sections

- No tubing manipulation required to set

-

Reduces installation time

Can be pinned in the fully stroked, closed or midway position - CRA materials available for hostile environments

OVERSHOT EXPANSION JOINT(OEJ) ASSEMBLY

ACT Overshot Expansion Joint (OEJ)

Assembly is designed for

applications where extreme tubing

movements are expected due to

stimulation or production of the

well and when a tubing separation

device is also required.

The OEJ assembly is a one-trip

system, which allows the well to be

flanged up prior to setting the

packer. The OEJ assembly

incorporates a slick joint sub as

well as housing – packing set

including working seal units and a

debris barrier above the working

seals. The plain receptacle, housing

– packing set and seals can be

retrieved when the tubing string is

recovered for maintenance or the

entire completion can be retrieved

by straight pull after ensuring that

J-pin engaged with J-slot, thus

allowing the packer to be retrieved.

The OEJ assembly is available in

varying lengths of up to 20 ft.

stroke. Adjustable shear pins lock

the inner & outer assembly together

during run-in. Once the shear screw

gets sheared by applying load, the

outer assembly gets disengaged and

it is free to move on the inner

assembly, compensating for tubing

movement.

FEATURES:

- One-trip required to run in and actuate

- Available in stroke lengths up to 20 ft.

- Debris barrier above the working seals

- Seating nipple located at the upper end of the slick joint sub

- Seals can be retrieved for redress

- One-trip retrieval – J-pin J-slot assembly allows the entire completion to be retrieved with straight pick up of the tubing once engaged

BENEFITS:

- No tubing manipulation required to set

- One-trip system saves rig time

- Seals can be retrieved for redress without removing packer

APPLICATIONS:

Completions in which the packer is

set after the well is flanged up.

HYDRAULIC OVERSHOT EXPANSION JOINT(HOEJ) ASSEMBLY

ACT Hydraulic Overshot Expansion

Joint (HOEJ) Assembly is designed

for applications where extreme

tubing movements are expected due to

stimulation or production of the

well and when a tubing separation

device is also required.

The HOEJ assembly is a one-trip

system, which allows the well to be

flanged up prior to setting the

packer. The HOEJ assembly

incorporates a slick joint sub as

well as housing – packing set

including working seal units and a

debris barrier above the working

seals. The plain receptacle, housing

– packing set and seals can be

retrieved when the tubing string is

recovered for maintenance or the

entire completion can be retrieved

by straight pull after ensuring that

J-pin is engaged with J-slot, thus

allowing the packer to be retrieved.

The HOEJ assembly is available in

varying lengths of up to 20 ft.

stroke. Hydraulic release mechanism

locks the inner & outer assembly

together during run-in. Once the

shear screw gets sheared by

hydraulic tubing pressure the outer

assembly gets disengaged and it is

free to move on the inner assembly,

compensating for tubing movement.

BENEFITS:

- No tubing manipulation required to set

- One-trip system saves rig time

- Seals can be retrieved for redress without removing packer

FEATURES:

- One-trip required to run in and actuate

- Adjustable hydraulic release mechanism

- Available in stroke lengths up to 20 ft.

- Debris barrier above the working seals

- Seating nipple located at the upper end of the slick joint sub

- Seals can be retrieved for redress

- One-trip retrieval – J-pin J-slot assembly allows the entire completion to be retrieved with straight pick up of the tubing once engaged

APPLICATIONS:

Completions in which the

packer is set after the well is

flanged up